What are the best practices for managing cold chain logistics for pharmaceuticals?

April 9, 2024

Introduction

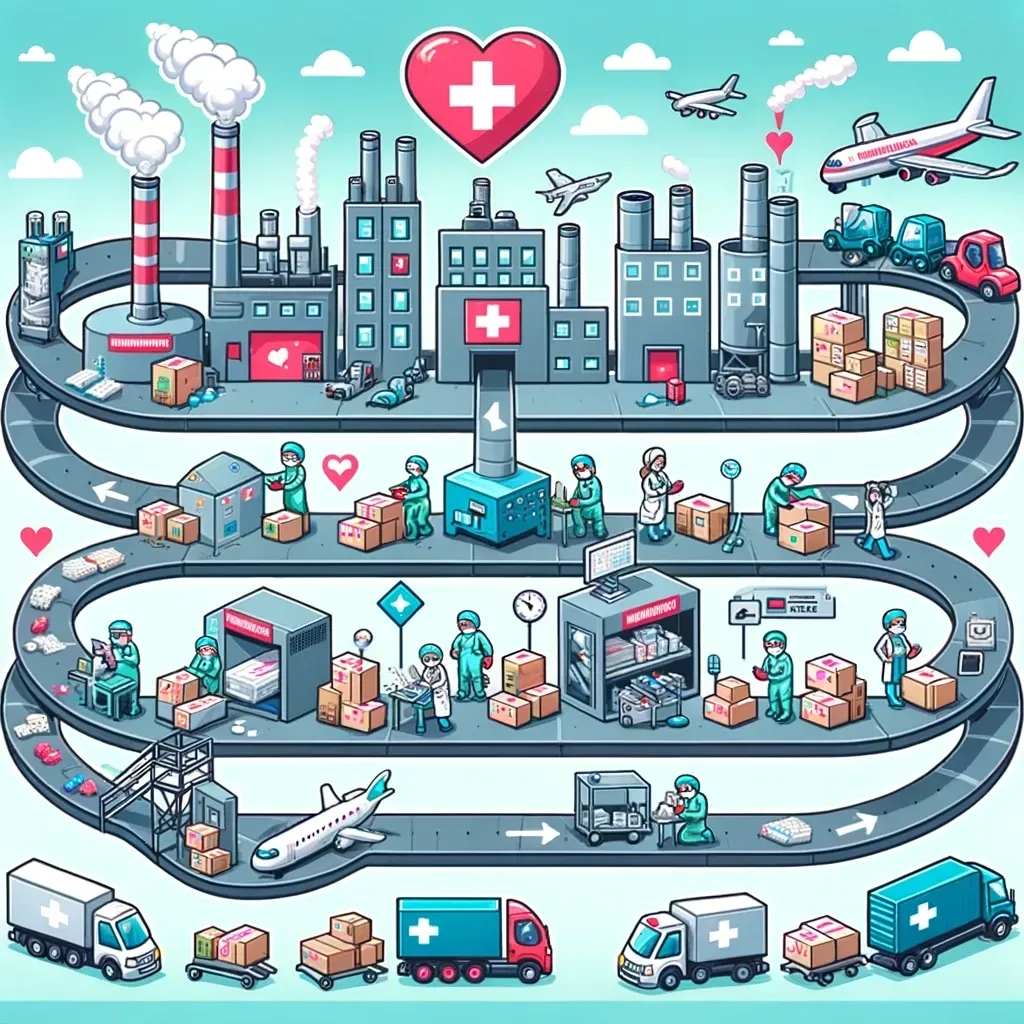

In the pharmaceutical industry, the integrity of products during storage and transit is non-negotiable. Cold chain logistics plays a pivotal role in this, ensuring that temperature-sensitive drugs, vaccines, and biologics maintain their efficacy from manufacture to delivery. However, managing a cold chain is fraught with challenges, from regulatory compliance to the risk of temperature excursions. This article outlines the best practices for navigating these complexities, guaranteeing that life-saving pharmaceuticals reach their destinations safely.

Understanding Cold Chain Logistics

Cold chain logistics refers to the transportation and storage of products that require specific temperature conditions. For pharmaceuticals, this means maintaining an unbroken cold chain to prevent degradation of medicines that could compromise their effectiveness. The stakes are high; even minor deviations can lead to significant financial losses and, more importantly, pose health risks to patients.

Best Practices for Managing Cold Chain Logistics

Temperature Monitoring and Control

Continuous monitoring is crucial for identifying and mitigating risks of temperature deviations. Best practices include using validated temperature-controlled packaging systems equipped with data loggers or temperature indicators. This ensures real-time monitoring and the ability to intervene promptly if temperatures breach predefined thresholds.

Packaging and Insulation Solutions

Innovative packaging and insulation materials can maintain stable temperatures for extended periods. Utilizing phase change materials (PCMs), vacuum-insulated panels, and other advanced solutions can significantly enhance the thermal protection of pharmaceuticals, catering to different segments of the cold chain.

Use of Technology and IoT for Real-time Tracking

The integration of Internet of Things (IoT) devices offers unparalleled visibility into the cold chain. GPS and RFID technologies enable real-time tracking of shipments, while IoT sensors monitor environmental conditions, ensuring immediate action can be taken to address any issues that arise during transit.

Risk Management and Contingency Planning

Developing comprehensive risk management strategies is essential for anticipating and mitigating potential disruptions. This includes analyzing historical data to identify common failure points, establishing alternative logistics routes, and having contingency plans for emergency situations such as power outages or natural disasters.

Regulatory Compliance and Documentation

Navigating the complex regulatory landscape is a critical component of cold chain management. Staying updated with local and international regulations and ensuring all necessary documentation is in order for customs clearance can prevent delays and ensure compliance. Regular audits and quality checks further reinforce adherence to standards.

Training and Capacity Building

Investing in training for all personnel involved in the cold chain is vital. From warehouse staff to drivers, ensuring everyone understands the importance of temperature control and the correct handling procedures can significantly reduce the risk of errors that could compromise product integrity.

Case Studies and Real-world Applications

Successful implementations of these best practices can be seen in various companies worldwide. For instance, a leading pharmaceutical firm utilized IoT-enabled devices for real-time temperature monitoring, drastically reducing the rate of temperature excursions during transit. Another example includes the use of advanced PCMs in packaging, allowing a vaccine manufacturer to extend its distribution network to more challenging climates.

Conclusion

Effective management of cold chain logistics for pharmaceuticals is a complex but essential task. Adhering to the best practices outlined above ensures that temperature-sensitive products are transported and stored under optimal conditions, maintaining their efficacy and safety. As technology advances and the pharmaceutical industry evolves, these practices will continue to be the cornerstone of successful cold chain management, safeguarding public health and ensuring the integrity of life-saving medications.

Introduction In an increasingly interconnected world, the global medical supply chain plays a crucial role in healthcare delivery. Its management requires meticulous planning, execution, and continuous improvement to address the challenges of global operations, such as regulatory diversity, logistical complexities, and the need for absolute reliability and transparency. Strategic Supplier Relationships Diversification and Partnership Relying on a single supplier or region for critical medical supplies can lead to vulnerabilities. Diversifying suppliers across different geographical areas can mitigate risks related to regional disruptions. Building strategic partnerships with suppliers ensures mutual understanding and collaboration, enabling better response to demand fluctuations and emergencies. Quality Assurance and Compliance Ensuring the quality of medical supplies is non-negotiable. Implementing rigorous quality assurance processes and regular audits of suppliers helps maintain high standards. Compliance with international and local regulatory requirements is critical, necessitating a thorough understanding of regulatory landscapes and active engagement with regulatory bodies. Advanced Technology Integration Leveraging Data Analytics Data analytics can provide insights into demand forecasting, inventory management, and risk assessment. Predictive analytics help anticipate supply needs, optimize stock levels, and prevent shortages or overstocking, ensuring the right supplies are available when and where they are needed. Blockchain for Transparency and Traceability Blockchain technology can enhance the transparency and traceability of the medical supply chain. It provides a secure, immutable record of transactions, enabling real-time tracking of products from manufacture to delivery, and ensuring the integrity and authenticity of medical supplies. Efficient Logistics and Distribution Optimized Transportation Networks Developing an efficient transportation network is crucial for timely delivery. Utilizing a mix of transportation modes and optimizing routes can reduce lead times and costs. Investing in logistics infrastructure, such as regional distribution centers, can improve the flexibility and resilience of the supply chain. Inventory Management Effective inventory management strategies, such as just-in-time (JIT) inventory or safety stock levels, can reduce waste and ensure availability. Advanced inventory management systems that provide visibility across the supply chain are essential for managing stock levels in real-time. Risk Management and Contingency Planning Identifying and Mitigating Risks Regularly assessing risks across the supply chain, from geopolitical issues to natural disasters, is essential. Developing a comprehensive risk management plan that includes mitigation strategies and contingency plans ensures preparedness for potential disruptions. Building Resilience Creating a resilient supply chain involves not only risk mitigation but also investing in capabilities that enable quick recovery from disruptions. This can include establishing alternative supply routes, maintaining strategic stockpiles, and fostering adaptability in operations. Sustainable Practices Environmental Responsibility Incorporating sustainable practices into the supply chain is increasingly important. This includes minimizing the environmental impact of packaging and transportation, responsibly disposing of medical waste, and ensuring the ethical sourcing of supplies. Social Responsibility Ensuring that the supply chain practices adhere to ethical labor standards and contribute positively to the communities involved is essential. Engaging in corporate social responsibility initiatives can enhance the reputation and sustainability of the supply chain. Stakeholder Collaboration and Communication Effective communication and collaboration among all stakeholders, including suppliers, logistics providers, healthcare providers, and regulatory bodies, are critical for the smooth operation of a global medical supply chain. Regular engagement and information sharing can improve responsiveness and agility. Continuous Improvement and Innovation Adopting a culture of continuous improvement and being open to innovation can drive efficiencies and enhance competitiveness. Staying informed about industry trends, technological advancements, and best practices ensures that the supply chain remains robust and responsive to the changing healthcare landscape. Conclusion Managing a global medical supply chain is a complex but vital endeavor that requires a strategic and integrated approach. By fostering strong supplier relationships, leveraging advanced technologies, optimizing logistics, implementing risk management practices, and committing to sustainability and continuous improvement, organizations can ensure the reliable, efficient, and ethical delivery of medical supplies worldwide. As the global healthcare landscape evolves, the ability to adapt and innovate will remain key to managing the challenges and opportunities of a global medical supply chain effectively.

Introduction In an increasingly globalized economy, the complexity of supply chains has escalated, presenting significant challenges in ensuring the integrity and traceability of products from manufacture to delivery. Blockchain technology offers a promising solution to these challenges, promising to redefine trust and security in supply chain management through its unique capabilities. Blockchain Fundamentals in Supply Chain Management Blockchain is a distributed ledger technology that allows data to be stored across a network of computers, making it nearly impossible to alter or hack. Each "block" in the chain contains a number of transactions; every time a new transaction occurs, a record of that transaction is added to every participant's ledger. This decentralized nature of blockchain ensures that no single entity has control over the entire chain, enhancing security and transparency. Enhancing Security Tamper-Proof Records Blockchain's immutable ledger means once a transaction is recorded, it cannot be altered or deleted. This immutability provides a tamper-proof record of every product's journey through the supply chain, from sourcing of raw materials to delivery to the end consumer. It significantly reduces the risk of fraud and errors, ensuring that all parties can trust the data within the blockchain. Decentralization The decentralized nature of blockchain eliminates a single point of failure, making it incredibly difficult for hackers to compromise the integrity of the supply chain data. By distributing the ledger across multiple nodes, blockchain ensures that even if one node is compromised, the overall system remains secure. Improving Tracking and Transparency Real-Time Tracking Blockchain enables real-time tracking of products as they move through the supply chain. Each transaction recorded on the blockchain, such as the transfer of goods from a manufacturer to a distributor, is timestamped and linked to the previous transaction, creating a chronological chain of custody. This level of detail provides unprecedented visibility into the supply chain, allowing companies to quickly identify and address bottlenecks, delays, or other issues. Transparency Across the Supply Chain With blockchain, every transaction is visible to all parties with permissioned access. This transparency fosters trust among supply chain participants, as manufacturers, suppliers, distributors, and retailers can all verify the authenticity and origin of products. It also empowers consumers to make informed decisions by tracing the provenance of the goods they purchase, from ethical sourcing to environmental impact. Applications in Various Industries Blockchain technology is not limited to a single industry; its applications span across various sectors, enhancing security and tracking in multiple supply chains. Pharmaceutical Industry In the pharmaceutical industry, blockchain can combat counterfeit drugs by providing a secure and transparent record of each medicine's production, verification, and distribution process. This ensures that only authentic, safe medications reach consumers. Food and Beverage Industry Blockchain enhances food safety by providing detailed tracking of food products from farm to table. In the event of a food safety scare, blockchain can quickly identify the source of contamination, enabling targeted recalls and reducing the risk of widespread health issues. Manufacturing and Electronics For manufacturing and electronics, blockchain offers a way to verify the authenticity of components and products, reducing the risk of counterfeit goods entering the market. It also allows companies to verify the ethical sourcing of materials, appealing to consumers increasingly concerned with corporate responsibility. Challenges and Future Directions Despite its potential, integrating blockchain into existing supply chain operations presents challenges, including technological complexity, the need for standardization, and ensuring the privacy of sensitive data. Overcoming these challenges requires collaboration between technology providers, industry stakeholders, and regulatory bodies. The future of blockchain in supply chain management is promising, with ongoing advancements and increasing adoption across industries. As more companies implement blockchain solutions, we can expect to see significant improvements in the security, efficiency, and transparency of global supply chains. Conclusion Blockchain technology stands at the forefront of transforming supply chain management by enhancing security, improving product tracking, and ensuring unparalleled transparency. Its ability to provide tamper-proof records, coupled with real-time tracking capabilities, not only combats issues of counterfeiting and fraud but also fosters trust among all participants in the supply chain, from producers to consumers. As industries continue to grapple with the complexities of global supply chains, blockchain emerges as a critical tool in building more secure, efficient, and transparent logistics networks. The continued exploration and adoption of blockchain will undoubtedly play a pivotal role in shaping the future of supply chain management.

Introduction The transportation and handling of hazardous medical materials, such as biohazardous waste, radioactive substances, and toxic chemicals, are fraught with challenges. These activities are essential components of healthcare operations, research, and diagnostics, yet they carry inherent risks to public health, safety, and the environment. Navigating these challenges requires a comprehensive understanding of the risks and a commitment to rigorous safety protocols. Regulatory Compliance One of the foremost challenges in managing hazardous medical materials is ensuring compliance with a myriad of regulations. These regulations vary by country and can include international standards, complicating cross-border transportation. Healthcare providers and logistics companies must stay informed about regulatory changes and implement procedures that meet or exceed these requirements to avoid legal repercussions and ensure public safety. Transportation Logistics The logistics of transporting hazardous medical materials are complex, requiring specialized vehicles, secure packaging, and precise routing to prevent accidents and contamination. Transporting radioactive materials, for instance, demands vehicles with shielding to protect handlers and the public from radiation exposure. Similarly, biohazardous materials require containment systems to prevent leaks or spills that could lead to contamination. Risk of Contamination The potential for contamination is a significant concern when handling hazardous medical materials. Improper handling or accidental spills can have dire consequences, including environmental damage and public health crises. Establishing and maintaining sterile conditions, particularly when transporting materials for medical use, is crucial to prevent contamination and ensure the safety of patients and healthcare providers. Training and Personnel Safety Ensuring the safety of personnel who handle, and transport hazardous materials is paramount. This challenge involves not only equipping them with the necessary personal protective equipment (PPE) but also providing comprehensive training on handling procedures, emergency response actions, and the correct use of containment and transportation equipment. Ongoing training and assessment are necessary to maintain high safety standards and adapt to regulatory changes or new hazards. Packaging and Labeling Requirements Proper packaging and labeling are critical to the safe transportation of hazardous medical materials. Packaging must be secure enough to prevent leaks or spills during transit, while labeling must clearly identify the contents, including hazard classifications and handling instructions. Meeting these requirements ensures that handlers and emergency responders can take appropriate precautions and actions in the event of an incident. Emergency Response Planning Despite rigorous safety protocols, accidents can occur, underscoring the importance of having a comprehensive emergency response plan. Such plans should include procedures for containment, decontamination, and medical treatment for exposure, as well as communication strategies to inform public authorities and the community. Preparation and quick response can mitigate the impact of an incident and protect public health and safety. Conclusion The challenges in handling and transporting hazardous medical materials are manifold, ranging from regulatory compliance and logistics to risk management and personnel safety. Addressing these challenges requires a multidisciplinary approach, combining expertise in healthcare, logistics, environmental science, and emergency response. By implementing stringent safety protocols, providing comprehensive training, and planning for emergencies, healthcare providers and logistics companies can mitigate the risks associated with hazardous materials, ensuring the safety of their personnel, the public, and the environment.

Introduction In today's global economy, supply chains are intricate networks that span continents, involving numerous stakeholders. The complexity of these networks makes them vulnerable to a variety of risks, from natural disasters and pandemics to geopolitical tensions and cyber-attacks. Effective risk management strategies are essential for preventing supply chain disruptions, ensuring operational continuity, and safeguarding against financial losses. By anticipating potential risks and preparing accordingly, businesses can enhance their resilience and maintain a competitive edge. Identifying and Assessing Risks The foundation of any robust risk management strategy lies in the systematic identification and assessment of potential risks. This process involves analyzing the supply chain to pinpoint vulnerabilities, whether they're in logistics, manufacturing, or information flow. Key risks include supplier insolvency, transportation delays, labor disputes, and technological failures. Assessing these risks involves evaluating their likelihood and potential impact on the supply chain, enabling businesses to prioritize their risk management efforts effectively. Developing a Risk Management Plan A comprehensive risk management plan outlines the steps a business will take to mitigate identified risks. This plan includes both preventive measures to lower the likelihood of disruptions and response strategies to manage and recover from incidents should they occur. Essential components of a risk management plan include contingency planning for critical supply chain functions, establishing crisis management teams, and setting up communication protocols to ensure timely and effective responses to disruptions. Strategies for Preventing Supply Chain Disruptions Diversification of Suppliers and Routes Reliance on a single supplier or transportation route is a significant vulnerability. Diversifying suppliers and logistics routes can prevent disruptions by ensuring alternative sources and pathways are available, minimizing the impact of regional crises, natural disasters, or political unrest. Investment in Technology and Automation Technological solutions like blockchain, IoT devices, and AI-powered analytics can enhance visibility across the supply chain, improving risk detection and response capabilities. Automation of critical processes can also reduce the likelihood of human error, enhancing overall supply chain resilience. Building Strong Relationships with Suppliers Fostering strong, collaborative relationships with suppliers ensures mutual understanding and commitment to risk management objectives. Regular communication and joint planning sessions can help identify potential risks early and develop cooperative strategies for mitigating them. Implementing Lean and Agile Practices Lean and agile supply chain practices, such as just-in-time (JIT) inventory management and flexible manufacturing systems, can increase the supply chain's responsiveness to disruptions. These practices help in quickly adapting to changing market conditions and consumer demands. Regular Monitoring and Review Continuous monitoring of the supply chain and the external environment allows for the early detection of emerging risks. Regularly reviewing and updating the risk management plan ensures that strategies remain effective and relevant in the face of evolving threats. Case Study: Successful Implementation of Risk Management Strategies A notable example of successful risk management in supply chains is the response of the automotive industry to the 2011 Thailand floods. By diversifying their supplier base and implementing flexible manufacturing strategies, several global automakers were able to minimize the impact of the floods on their operations, demonstrating the value of proactive risk management. Conclusion Risk management strategies are indispensable for preventing supply chain disruptions. By identifying and assessing risks, developing comprehensive risk management plans, and implementing targeted strategies, businesses can safeguard against the wide array of potential disruptions facing modern supply chains. As global supply chains continue to evolve, the adoption of robust risk management practices will be critical for ensuring resilience, maintaining operational continuity, and securing long-term success.

Introduction The healthcare sector, characterized by its dynamic demands, regulatory complexities, and the critical need for reliability, finds a vital partner in third-party logistics (3PL) providers. These entities specialize in the management and execution of logistics operations, from warehousing and distribution to transportation and inventory management, on behalf of healthcare companies. By leveraging the expertise and resources of 3PL providers, healthcare organizations can enhance their focus on core medical services, ensuring patient care remains at the forefront of their mission. The Expanding Role of 3PL Providers in Healthcare Efficient Distribution and Warehousing 3PL providers optimize healthcare logistics by ensuring the efficient distribution of medical products. They manage sophisticated warehousing operations equipped with climate-controlled environments essential for storing temperature-sensitive pharmaceuticals and medical devices. Through advanced inventory management systems, 3PLs maintain optimal stock levels, reducing waste and mitigating the risk of shortages. Regulatory Compliance and Quality Assurance Navigating the regulatory landscape of the healthcare sector is a significant challenge for medical suppliers. 3PL providers, well-versed in global and local regulations, ensure compliance across the supply chain. This encompasses handling approvals, managing documentation, and ensuring products meet quality standards, thereby safeguarding patient safety and product efficacy. Flexibility and Scalability The fluctuating demand in healthcare necessitates a flexible and scalable logistics approach. 3PL providers offer adaptability, scaling operations up or down based on current needs without compromising service quality. This elasticity is crucial during health emergencies or market expansions, enabling healthcare organizations to respond swiftly to changing scenarios. Cost Reduction and Operational Efficiency By outsourcing logistics to 3PL providers, healthcare organizations can achieve significant cost savings. Economies of scale, coupled with the 3PLs' expertise in logistics optimization, reduce transportation and operational expenses. Furthermore, this partnership allows healthcare entities to invest more resources into patient care and innovation, enhancing overall operational efficiency. Technology and Innovation 3PL providers bring to the table advanced technological solutions that streamline logistics operations. From real-time tracking systems and data analytics to AI-driven forecasting models, these technologies offer transparency, improve decision-making, and enhance supply chain visibility. The adoption of such innovations is pivotal in meeting the evolving demands of healthcare logistics. Challenges in the 3PL-Healthcare Partnership Despite the advantages, the partnership between healthcare organizations and 3PL providers is not devoid of challenges. Data security concerns, especially related to patient information and proprietary medical data, remain paramount. Additionally, the seamless integration of 3PL operations with the healthcare providers' systems requires robust communication channels and technological compatibility. Addressing these challenges is essential for fostering a productive and secure collaboration. Future Prospects The future of 3PL in healthcare points towards deeper integration and collaboration. With the advent of blockchain technology, for instance, 3PL providers could offer even more secure and transparent supply chain solutions. The continuous evolution of technology, along with an increasing focus on sustainability, also suggests that 3PL providers will play a crucial role in developing greener logistics practices within healthcare. Conclusion Third-party logistics providers have become indispensable allies of the healthcare sector, facilitating not just the timely delivery of medical supplies but also contributing to operational efficiency, regulatory compliance, and cost-effectiveness. As the healthcare landscape continues to evolve, the role of 3PL providers will undoubtedly expand, becoming more integrated and essential to healthcare delivery. Embracing this partnership, while navigating its challenges, will be key for healthcare organizations aiming to enhance service quality and patient care in an increasingly complex and demanding environment.

Introduction In the quest for a more sustainable future, the healthcare sector stands at a critical juncture, especially within the realm of medical logistics. The delivery of medical supplies, pharmaceuticals, and equipment encompasses a significant environmental footprint, from greenhouse gas emissions to waste generation. Integrating sustainability into medical logistics is essential not only for reducing environmental impact but also for enhancing healthcare delivery and ensuring economic viability. This shift towards sustainable practices represents a holistic approach to healthcare, where patient care is aligned with environmental stewardship. Challenges in Medical Logistics Integrating sustainability into medical logistics presents several challenges. Regulatory compliance requires navigating a complex web of healthcare and environmental laws, which can vary significantly across regions. The cost implications of adopting sustainable practices, such as investing in eco-friendly materials or renewable energy sources, pose financial challenges, particularly for resource-constrained healthcare systems. Additionally, systemic changes demand a shift in mindset and operations across the supply chain, from manufacturers to healthcare providers. Strategies for Sustainable Medical Logistics Eco-friendly Packaging and Materials Transitioning to sustainable packaging options—such as biodegradable, recyclable, or reusable containers—can significantly reduce waste and environmental impact. This strategy involves evaluating the lifecycle of packaging materials and opting for solutions that minimize ecological footprints without compromising the safety and integrity of medical supplies. Optimizing Transportation and Reducing Carbon Footprint Adopting more efficient transportation methods and logistics planning can substantially lower carbon emissions. This includes utilizing electric or hybrid vehicles for last-mile delivery, optimizing route planning to reduce fuel consumption, and considering alternative modes of transportation, such as rail, which have lower carbon footprints compared to road transport. Renewable Energy in Supply Chain Facilities Incorporating renewable energy sources, such as solar or wind power, into supply chain facilities can dramatically decrease the reliance on fossil fuels. Warehouses, distribution centers, and other logistics infrastructures can be designed or retrofitted to harness renewable energy, contributing to a greener supply chain. Waste Reduction and Recycling Initiatives Implementing systematic waste reduction and recycling initiatives across the medical supply chain is crucial. This includes not only recycling or safely disposing of packaging materials but also managing medical waste in compliance with environmental and health standards. Strategies such as reverse logistics can facilitate the return of used products for recycling or proper disposal. Digitalization and Technology Integration Leveraging digital technologies and data analytics can enhance the efficiency and sustainability of medical logistics. Digital tools can optimize inventory management, reducing overstock and waste, while data analytics can improve demand forecasting and route planning. Moreover, digital documentation reduces the need for paper, contributing to waste reduction. Stakeholder Engagement and Policy Advocacy Collaboration among all stakeholders, including manufacturers, healthcare providers, and governments, is essential for advancing sustainability in medical logistics. Engaging stakeholders in dialogue and advocacy can drive the adoption of policies and practices that support sustainable logistics, creating a more conducive environment for systemic change. Case Studies of Sustainable Practices in Medical Logistics Several organizations have successfully integrated sustainability into their medical logistics operations. For instance, a leading pharmaceutical company implemented a comprehensive green logistics program, focusing on eco-friendly packaging, optimized transportation, and renewable energy use in its distribution centers. These initiatives not only reduced the company's environmental footprint but also resulted in cost savings and improved supply chain resilience. Conclusion The integration of sustainability into medical logistics is a multifaceted endeavor that requires commitment, innovation, and collaboration. By adopting eco-friendly materials, optimizing transportation, leveraging renewable energy, and embracing digitalization, the healthcare sector can significantly mitigate its environmental impact. These sustainable practices not only contribute to environmental conservation but also enhance healthcare delivery and economic efficiency. As the global community strives for a sustainable future, the healthcare sector must lead by example, ensuring that medical logistics operations are aligned with the principles of sustainability and responsible stewardship of resources.

Introduction The medical supply chain is a critical component of global healthcare, responsible for delivering medicines, devices, and supplies that save lives and maintain health. However, beyond logistical efficiency and regulatory compliance, there lies a complex landscape of ethical considerations. These range from ensuring equitable access to essential medical supplies to upholding environmental and labor standards. Addressing these ethical considerations is vital not only for the integrity of healthcare providers but also for the trust and safety of patients worldwide. Transparency and Traceability Transparency in the medical supply chain is fundamental to ethical operations, requiring clear visibility into the sourcing of materials and the manufacturing processes of medical products. Traceability, or the ability to track the journey of a product from production to delivery, is equally critical. It ensures that products meet quality and safety standards, allowing for the swift recall of defective items. Ethically, transparency and traceability are pillars of accountability, assuring healthcare providers and patients of the legitimacy and safety of medical supplies. Equitable Distribution Equitable distribution presents a significant ethical challenge, particularly evident during global health crises like the COVID-19 pandemic. The tendency for wealthier nations to secure large quantities of medical supplies, including vaccines, at the expense of poorer regions highlights a profound ethical dilemma. Ensuring equitable access to medical supplies across different geographies and socioeconomic statuses is a moral imperative, critical to addressing health disparities and fostering global health equity. Environmental Responsibility The environmental impact of the medical supply chain, from production through disposal, poses substantial ethical considerations. The use of non-renewable materials, energy-intensive manufacturing processes, and the generation of medical waste are areas of concern. Ethically, there is a responsibility to minimize environmental harm through sustainable practices, such as using recyclable materials, optimizing logistics to reduce carbon emissions, and properly managing waste, especially hazardous by-products. Labor Rights and Fair Trade Ethical sourcing in the medical supply chain extends to labor practices. It involves ensuring fair wages, safe working conditions, and respecting workers' rights throughout the production process. The use of child labor or exploitative labor practices in manufacturing facilities, often located in low-income countries, raises serious ethical issues. Committing to fair trade principles and rigorously auditing supply chain partners for compliance are ethical obligations for companies involved in the medical supply industry. Counterfeit Products and Intellectual Property The proliferation of counterfeit medical products poses significant ethical and safety risks, potentially endangering lives. Combatting counterfeit products requires a concerted effort from all stakeholders, underpinned by robust legal and ethical frameworks. At the same time, the protection of intellectual property must be balanced with the ethical imperative to ensure access to essential medicines, especially in low-income regions. Navigating the tension between encouraging innovation and preventing monopolistic practices that restrict access to crucial medical supplies is a key ethical challenge. Conclusion The ethical considerations in the medical supply chain encompass a wide range of issues, from ensuring transparency and equitable distribution to minimizing environmental impact and upholding labor rights. Integrating ethical practices into every aspect of the supply chain is not just a moral duty but a foundational element for trust and effectiveness in healthcare delivery. As the global health landscape evolves, so must our commitment to these ethical principles, ensuring they guide actions and decisions across the medical supply chain.

Introduction Healthcare policies significantly influence the framework within which medical logistics and supply chain management operate, affecting everything from pharmaceutical distribution to the availability of medical supplies. These policies, designed to ensure safety, efficacy, and equitable access, can have far-reaching implications for the efficiency and reliability of supply chains. This article delves into how healthcare policies impact medical logistics, highlighting key areas of influence and their operational consequences. Overview of Healthcare Policies Relevant to Logistics and Supply Chain Healthcare policies encompass a wide range of regulations and guidelines, from drug approval processes and quality assurance to import/export restrictions and handling requirements for sensitive materials. Policies such as the Drug Supply Chain Security Act (DSCSA) in the United States or the Falsified Medicines Directive (FMD) in the European Union exemplify regulatory efforts to secure and monitor the pharmaceutical supply chain. These policies aim to protect public health but also impose specific operational requirements on supply chain stakeholders. Impact on Pharmaceutical and Medical Equipment Distribution Healthcare policies dictate the terms under which pharmaceuticals and medical equipment are distributed, significantly affecting logistics operations. Regulatory compliance, for instance, mandates rigorous documentation and verification processes to track product movement from manufacturer to end-user. Import/export restrictions can limit or delay the cross-border flow of critical medical supplies, necessitating strategic planning to ensure uninterrupted supply. Additionally, distribution practices must adapt to policies promoting generic drug use or restricting certain materials, shaping inventory and distribution strategies. Influence on Inventory Management and Demand Forecasting Effective inventory management and accurate demand forecasting are pivotal for maintaining optimal levels of medical supplies. Healthcare policies influence these areas through regulations on stockpiling, which may mandate minimum or maximum inventory levels for critical medications. Expiry management is also impacted by policies requiring specific handling and disposal procedures for expired or unused medications. Furthermore, data sharing policies facilitate or hinder the exchange of information across the supply chain, affecting the accuracy of demand forecasting and collaborative planning efforts. Effects on Transportation and Storage Requirements Transportation logistics and storage requirements are directly impacted by healthcare policies. Regulations specifying the transportation of hazardous materials or temperature-sensitive products dictate the methods and infrastructure required for compliant shipping. Storage conditions for pharmaceuticals and medical equipment, enforced through policies, require facilities to implement specific environmental controls, security measures, and inventory tracking systems. These regulations ensure product integrity but also demand significant logistical adaptations and investments. Challenges and Opportunities for Improvement While healthcare policies aim to safeguard public health, they can also pose challenges to medical logistics and supply chain management. Compliance with diverse and evolving regulations requires constant vigilance and adaptability, often at a significant cost. These challenges, however, present opportunities for policy improvement. Streamlining regulatory processes, enhancing transparency and collaboration across the supply chain, and investing in infrastructure and technology could mitigate the logistical burdens while upholding safety and quality standards. Conclusion Healthcare policies play a pivotal role in shaping the operational landscape of medical logistics and supply chain management. While designed to ensure the safety, quality, and accessibility of medical supplies, these policies also impose specific challenges that require strategic and operational adjustments. Recognizing and addressing the impact of healthcare policies on logistics operations is crucial for maintaining efficient, responsive, and resilient medical supply chains, ultimately supporting improved healthcare delivery and patient outcomes.

Introduction Delivering medical supplies to remote areas is a critical yet challenging task for global health systems. The geographical isolation, lack of infrastructure, and unpredictable conditions of these regions demand innovative and resilient strategies to ensure that life-saving medicines and health products reach those in need promptly. The stakes are high, as delays or failures can have dire consequences for population health. This article explores comprehensive strategies combining logistics, technology, and community engagement to overcome these barriers. Logistical Strategies Localized Distribution Centers Establishing distribution centers closer to remote areas can significantly reduce delivery times and improve supply chain responsiveness. These hubs can serve as central points from which supplies are distributed to surrounding areas, minimizing the distance covered by the last-mile delivery efforts. Diversified Transportation Methods Employing a mix of transportation methods—ranging from conventional vehicles to motorcycles and boats—can navigate the diverse and often challenging terrains of remote areas. Flexibility in transportation allows for adapting to seasonal changes and overcoming unforeseen obstacles, ensuring continuous supply flow. Technological Innovations Drone Delivery Systems Drones represent a groundbreaking solution for reaching isolated communities. Their ability to fly directly to destinations and land in limited spaces makes them ideal for delivering small, critical shipments of medicines and vaccines, bypassing the need for conventional transportation routes. AI and Data Analytics for Forecasting Artificial intelligence (AI) and data analytics can optimize inventory management and predict demand in remote areas. By analyzing consumption patterns and external factors affecting supply needs, these technologies can anticipate shortages and adjust stock levels proactively, reducing the risk of stockouts. Community-Based Approaches Local Healthcare Worker Engagement Training and involving local healthcare workers in the supply chain process can enhance the efficiency of distribution efforts. These workers understand the community's specific needs and challenges, enabling them to identify the most effective delivery routes and methods. Partnerships with Local Organizations Collaborating with local organizations and NGOs can leverage existing networks and resources for supply distribution. These partnerships often bring valuable insights into community dynamics and logistical expertise, facilitating smoother and more culturally sensitive delivery operations. Policy and Infrastructure Support Supportive policies and investment in infrastructure are fundamental to improving supply delivery to remote areas. Government and international agencies can play a crucial role by funding transportation networks, communication systems, and storage facilities, creating a more favorable environment for implementing the strategies discussed. Conclusion Ensuring the timely delivery of medical supplies to remote areas requires a multifaceted approach, integrating logistical planning, technological innovation, and community engagement. By leveraging localized distribution centers, diversifying transportation methods, adopting drone technology, and fostering partnerships, the delivery process can be significantly enhanced. However, the success of these strategies also depends on supportive policies and infrastructure development. A collective effort from governments, NGOs, healthcare providers, and communities is essential to overcome the challenges and ensure that every individual, no matter how remote their location, has access to necessary medical supplies.

Introduction In the realm of healthcare, the efficiency of hospital operations is pivotal to delivering high-quality patient care. Central to these operations is inventory management—a critical yet complex task that involves maintaining an optimal balance of medical supplies, medications, and equipment. Traditional approaches, often manual and time-intensive, are increasingly unable to meet the demands of modern healthcare settings. Enter artificial intelligence (AI) and machine learning (ML), technologies poised to revolutionize inventory management in hospitals by enhancing accuracy, reducing waste, and improving overall efficiency. Challenges in Hospital Inventory Management Effective inventory management in hospitals faces several significant challenges that can impact operational efficiency and patient care: 1. Overstocking and Understocking: Balancing inventory levels is crucial. Overstocking consumes valuable storage space and resources, while understocking can lead to shortages of critical supplies, endangering patient health. 2. Perishable Supplies: Many medical supplies and medications have limited shelf lives. Managing these items requires precise tracking and timely utilization to minimize waste due to expiration. 3. Variability in Demand: Patient influx and medical emergencies can lead to sudden changes in demand for supplies and equipment, making it difficult to predict inventory needs accurately. 4. Manual Processes: Reliance on manual processes for inventory management is not only time-consuming but also prone to errors, leading to inaccuracies in inventory records. 5. Regulatory Compliance: Hospitals must adhere to strict regulatory requirements regarding the storage and handling of medical supplies, further complicating inventory management. 6. The integration of AI and ML into hospital inventory management systems presents a promising solution to these challenges, offering the potential to transform this critical aspect of healthcare operations. Integrating AI and ML into Hospital Inventory Management Predictive Analytics for Demand Forecasting AI and ML excel in analyzing vast amounts of data to identify patterns and predict future outcomes. In hospital inventory management, these technologies can process historical usage data, consider seasonal trends, and account for upcoming events to accurately forecast future demand for various supplies and medications. This predictive capability allows hospitals to adjust their inventory levels proactively, ensuring adequate supplies are available to meet patient needs without resorting to overstocking. Automated Reordering Systems ML algorithms can automate the reordering process by continuously monitoring inventory levels and automatically initiating purchase orders when supplies fall below predetermined thresholds. These systems can also adjust reorder quantities over time based on changing demand patterns, further optimizing inventory levels and reducing the risk of shortages or excess stock. Real-time Tracking and Monitoring Incorporating IoT devices with AI and ML enables real-time tracking of inventory items, providing immediate visibility into stock levels, locations, and conditions (such as temperature for temperature-sensitive items). This integration facilitates timely decision-making and interventions, ensuring that inventory management processes are responsive to the dynamic needs of the hospital. Waste Reduction and Expiry Management AI and ML can significantly enhance the management of perishable items by identifying supplies nearing expiration and prioritizing their use or redistribution. By analyzing usage patterns, these technologies can also optimize ordering practices to reduce the quantity of perishable items that expire before use, thereby minimizing waste and associated costs. Streamlining Manual Processes By automating routine inventory management tasks, AI and ML free hospital staff to focus on more critical duties. Automated systems can handle tasks such as record-keeping, order processing, and inventory audits, reducing the time and effort required by manual processes and decreasing the likelihood of errors. Benefits of Optimized Inventory Management The application of AI and ML in hospital inventory management brings several key benefits: 1. Enhanced Operational Efficiency: Automating and optimizing inventory management processes reduce the time and resources required to maintain optimal inventory levels. 2. Improved Patient Care: By ensuring the timely availability of necessary medical supplies and equipment, hospitals can provide better and more efficient patient care. 3. Cost Savings: Reducing overstocking and waste, particularly of perishable items, leads to significant cost savings for hospitals. 4. Increased Accuracy: AI and ML provide more accurate demand forecasting and inventory tracking, reducing errors and inefficiencies in the supply chain. 5. Regulatory Compliance: Automated systems can help ensure that inventory management practices comply with relevant regulations and standards, reducing the risk of violations. Challenges and Considerations Implementing AI and ML solutions in hospital inventory management is not without its challenges. Hospitals must consider the initial investment in technology, the need for staff training, and the integration of new systems with existing processes. Additionally, ensuring the security and privacy of data within AI and ML systems is paramount. Conclusion The potential of artificial intelligence and machine learning to optimize inventory management in hospitals is immense. By addressing the key challenges of inventory management and leveraging the capabilities of these technologies, hospitals can achieve significant improvements in efficiency, cost savings, and patient care. As healthcare continues to evolve, the integration of AI and ML in hospital operations will undoubtedly play a critical role in shaping the future of patient care delivery.

Share On: